ABA co-extrusion film blowing machine enjoys advantages in producing HDPE, LDPE and LLDPE material. The strength of plastic film is improved by co-extrusion. Besides, with only two extrusion units, this model achieves function of three layer film blowing machine. One unit deals with inner&outer layer, while the other deals with inner stuffing layer. In this way, costs are reduced and energy is saved. Meanwhile, to enhance market competitiveness of customers, it's possible to add recycled material and CACO3 into inner puffing layer at the rate of 80% of full amount.

ABA Co-extrusion Film Blowing Machine:

Products made by ABA film blowing machine is widely used in many fields. For example, t-shirt shopping bags.biodegradable plastic film and packaging for fruits.

Use Of Recycled Material And CACO3:Using recyled material and CACO3 and save a lot compared with using new material. Our film blowing machine uses A layer as coating layer for inputting. This way, plastic film is smooth and bright and is of great anti-stretchability. As for the inner layer, we use recycled material and CAC03 for stuffing. Single layer film blowing machine can not achieve such function. Compared to three layer film blowing machine, costs are saved.

Advantages Of Co-extrusion ABA Film Blowing Machine:

Speciality Of Extruders :

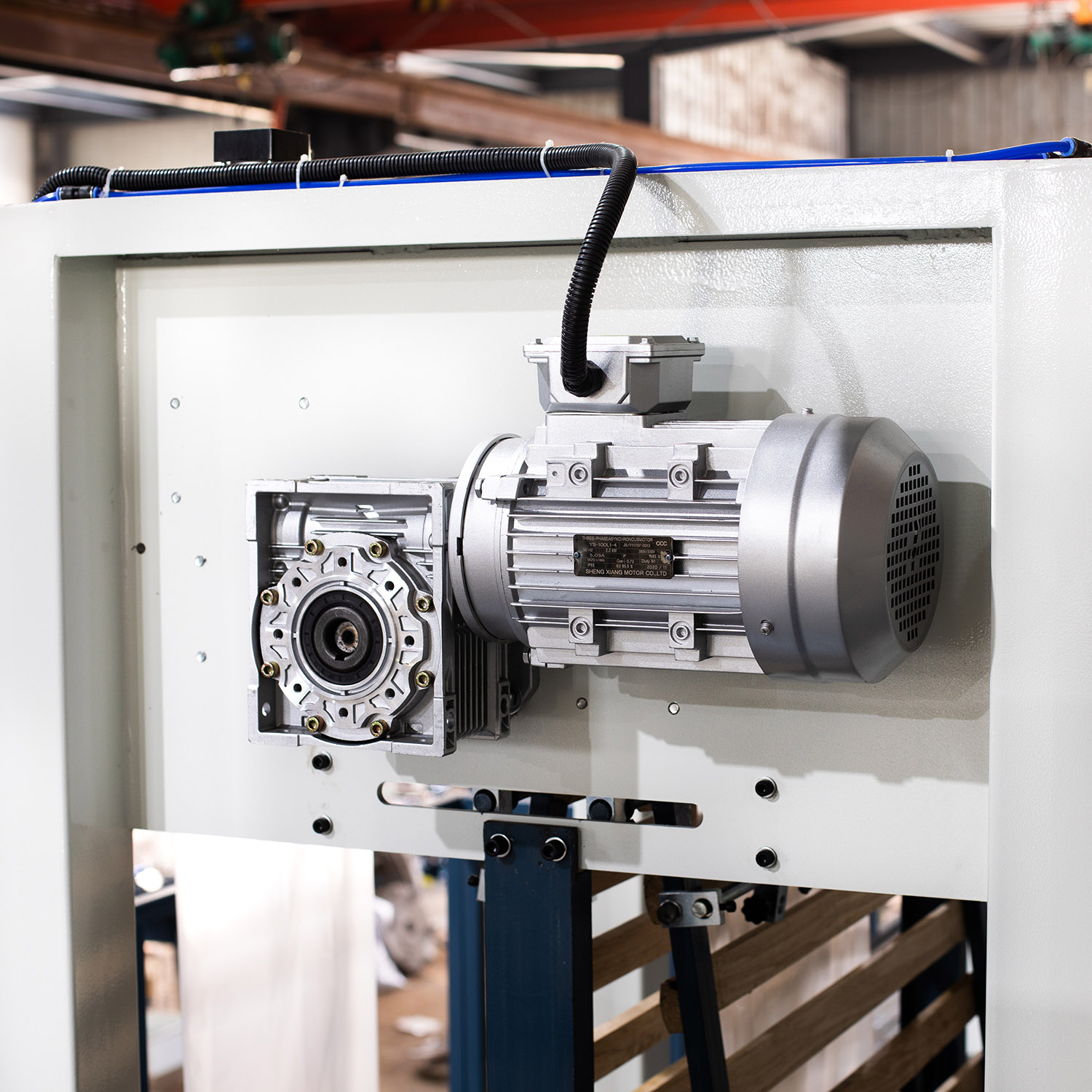

In the engine, this machine uses two screws and achieves the function of three layer film blowing machine. The main part of machine is scientifically designed to save costs and improve effeciency.

Easy Operation:

Automatic material feeding system. The screw in B layer adopts auto fast net changer and saves time. Besides, rewinding unit is designed in a automatic rewinding changing way. Automatic roller changing is flexible and can be adjusted according to length, weight and etc specification. One experienced worker can handle all situations of this machine, making production more easier and saving costs of manpower.

A Quick Recall Of Investment:

After buying this machine, customers can get a quick recall of investments by using cheaper raw material. Besides, profit is very promising.